|

Abstract:

The

scientific inspect testing technique wire ropes

on line is a difficult problem that internal and

external science technique do not have

surmounted yet. With the development of the

modern computer and the information technique,

people have a platform for the solvable this

difficult technical problem finally.

This

article proceeds from the importance of the wire

ropes testing on line. Describing on this

platform mainly a chi eve the basic principle,

key technique, theoretical estimation of the

active service wire ropes scientific tests on

line and the real time. Quantitative results

testing on line for laboratory

Keywords:

Online wire ropes inspect testing technique

practice active service

Main

Catalogue

1.

Background (Importance, Basic Principle and

Research History)

2.

Constitution

(Sensor,

Processing Circuit Analysis Safe Ware Result

estimation)

3.

Index (Aim of Inspect Testing)

4.

Results (Laboratory Data)

5.

Reference Literature

1.

Background

(1)

Origin

The

coal mine and metallurgical mine took place the

accident for lifting the broken wire in wire

ropes. The reason is caused by internal wire

rope. Such as corrosion and broken wire etc,

flaw. That is unable discovery with the people’s

naked eyes.

(2)

Importance

The

wire ropes are a flexible component part in

extrusive application to the engineering. The

wire rope is always key component; even more it

is the lifeblood in operation. In order to

ensure wire ropes for working in safety,

reliability, higher efficiency, it is necessary

for the operation condition of the wire rope

(such as broken wire, abrasion, corrosion flaw

and metal fatigue, remainder load-carrying

ability, assurance coefficient etc.) to proceed

testing. The traditional wire rope testing

Method is artificial visual examination. This

method is that the inspectors proceed to observe

the active wire rope regularly. Adopt calipers

measure the diameter of the wire rope, feel by

hard or seek the flaw with naked eyes.

Obviously, Artificial visual examination can

only discover the bare outer part flaw (for

example broken wire), regard to the internal

flaw is powerless. It would not be examined

about the lose sight of wire ropes (or wire

ropes section) flaw with the naked eyes. And it

would be influenced relatively large by

artificial factor. The reliability of the

testing results are poor. There fore, many usage

departments for wire ropes adopt changing the

wire ropes methods regularly: According to the

rated service life for the wire ropes as certain

their changing cycle. No matter how the

practical condition is, all wire ropes carry out

changes at maturity. Obviously this can bring

some questions.

So

adopt instrument proceed testing especially

quantitative nondestructive testing is very

important. This importance express in the

following three respects.

①

Make

out from wire rope application safety

In

the course of the application, the wire ropes

can’t avoid to produce the flaw of metal fatigue

and abrasion, corrosion, deformation, rupture

etc. Thus lead to wire ropes intensity decrease.

Even be destroyed suddenly. The wire ropes take

place the destructive accident in application.

The damage of equipment. The many accidents that

the Casualties of the personnel. It was many

accidents that the typical cases are reported

publicly.

For

example, the 12 persons were killed for

ropeway-hauling rope was ruptured at Bedenmale,

Switzerland in 1972. The 4 persons were killed

for ropeway-hauling rope was ruptured at Begem,

Norway in 1974. The 43 persons were killed for

ropeway-hauling rope was ruptured at Kavale,

Italy in 1976. The wire ropes of the suspension

bridge were ruptured at Da County, Szechwan

Province, China in 1986, caused the

31Casualties. A foreign ship was at anchor in

Shanghai, China in 1987. It crashed on Baogang

Transport Material Bridge Creation huge

economical loss is caused by the fixed wire

ropes rupture out of control. Climbing ropeway

wire ropes ruptured at Tbilisi, former Soviet

Union in 1990 caused the 55 casualties. In 1990,

along-scale floating crane ship of Wu Chang

shipyard lower floating dashed upon the NO4

bridge pier of Wu han Yang tze Bridge is caused

by the fixed wire ropes ruptured out of control.

Not only it bring about tremendous economic

loss, but also bring about long-term hidden

danger of local serious internal injury in

bridge. These cases are too numerous to mention

individually. It relates to many countries and

almost all departments for the wire ropes

application. There fore, the people attach great

importance to the safety for the wire ropes in

active service.

In

order to take preventive measures. In view of

application problems for wire ropes, many

countries formulated the safety Regulations of

the corresponding trade or the state detection

standard early. But, why do the accidents being

caused by the wire rope destroys take place for

sometimes, impossible to defend effectively? It

is the important reason that is short of the

testing method and evaluation measure under

reliable wire rope condition at present, yet. At

over sea market, there have been formed many

products of the wire ropes testing for recent

years. But because of function wasn’t satisfied

with meeting the requirement of worksite

popularization application. Only a few important

departments take them as the auxiliary testing

tools proceeding the management and maintenance

for the wire ropes. The more application

departments for the wire ropes still adopt the

methods of the artificial examination and the

regular change. On the other hand because of the

accuracy and reliability of existing testing

instruments were not enough. Even if the

departments that adopt the instrument testing

wire ropes application, have taken place the

accident, such as broken wire sometimes. At

domestic manufacture, at present, the most

application departments for wire ropes adopt the

methods of the Artificial Visual Examination and

the regular change. With the result that the

accidents are happening with increasing

frequency.

②

Make

out from wire rope application economization

The

wire ropes can always produce the whole piece of

wire rope scrap for one local defeat. The

Artificial Visual examination is limited in the

attention concentration degree and experience of

the inspector. Thus the artificial visual

examination exists in the unreliability and the

localization. On the other hand appear as the

broken wire and the problems of unprecedented

concentrated corrosion etc, in the wire ropes

much more than anticipative cases for the change

of the environment and condition of the wire

rope, when the condition is serious, internal

degraded wire ropes wouldn’t be discovered from

their appearances at all. The regular change

exists in blindness this way. There fore the

Artificial Visual Examination and regular change

the wire ropes. Not only it take place the

danger of wire rope destruction potentially for

the unreliability of testing, but also bring

about enormous waste for unreason able change to

cause wire rope scrap.

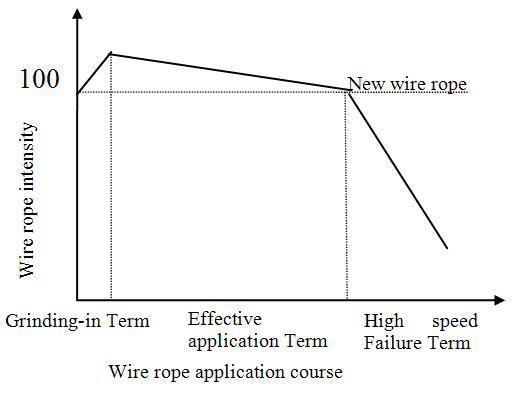

In

1984, A statistical analysis made in USA of over

8,000 laboratory and field test records revealed

some interesting facts on the condition of wire

rope in services. The results make known that

approximately 10 percent of all ropes considered

showed a strength loss of over 15 percent. The

strength loss of over 20% is more than the

specified strength loss of 30%. That is to say,

the wire ropes in services, approximately 10%,

there are still potentially hazardous. More than

2 percent of the ropes had exceeded the

specified strength over 30 percent wire ropes

were in an extremely dangerous condition. On the

other hand, more than 70 percent of all ropes in

the sample were removed from service with little

of no strength loss. According to Japanese

statistical results also make known that more

than 50 percent of all ropes in the sample were

removed from service, the strength attaining

over 90 percent of the new products, even than

over 100 percent. Namely they are in running in

the period of application. In 1985, according to

the statistical results of China Coal Industry

Ministry offered these numeral: If this

instrument had been adopted for the wire ropes

state to proceed with monitor, used suitable lip

lubrication, (had been) saved, and (have been)

saved the amount of the import wire rope foreign

currency used from 20 percent to 30 percent.

③

The

Maintenance for wire ropes

The

mainest, the onerous work is the routine

examination for the maintenance of the wire

ropes in ordinary service time besides needing

lubrication. In order to guarantee the safe

operation for wire ropes, every wire ropes

application units have formulated strict rules

and regulations on the basis of corresponding

trade safe norm and the state inspection

standard. Demand practicing shift inspection,

day inspection, and week inspection month

inspection season inspection annual inspection

and emphatically overhaul institution commonly.

In the light of our country at present,

above-mentioned institution implement is all

major method with artificial visual examination.

On account of the artificial visual examination

is with the observation in the lead. The

operating speed of the wire ropes can’t too fast

in the course of the inspection. Demand under

0.3m/s commonly. But, the length of the wire

ropes application in situ is hundreds meters

long comely. Testing one time needs much time

consequently. The inspectors are easy tired, the

intension of labor is high and the efficiency is

low. This is waste of much treasure time and has

influence upon the heightening of labor force on

the other hand; the artificial visual

examination is required higher for the

operators. It would be necessary to train such

personnel for quite along time. The major

problem is that this method can only check in

slght of wire rope section with artificial

visual examination. But some flaw is given up

out of sight of the section and internal with in

the wire ropes. It can’t practice the inspection

of the whole course and completion. This become

even more decrease its testing reliability.

Thus, this is caused by wire ropes the accident

occurs frequently. For example, Dukou Mineral

affaire Bureau, Szechwan Province, China

preceded the statistics analysis about transport

ropeway accidents from 1970 to 1985. The results

make clear that the wire rope accident is 90

times. It accounts for 16 percent of the

accident sum total. It causes off the line 734

hours, 24 percent of off the line hours sum

total. Shanghai Port Authority happens with in

the machine damage accidents. Among them, about

33 percent is cause by the wire ropes accidents.

When testing the instrument. Not only the wire

ropes operating speed can heighten to several

meter per second even teen meter per second, but

also can achieve over all testing with whole

course and there fore can ensure its safe

operation, decrease the accidents, lighten the

intensity of lab our, heighten the productivity.

As

mentioned above, accidents occur frequently on

account of the wire ropes testing measures can’t

be proved effective thought practicing

item-by-item sequential inspection of the wire

ropes with much more energy and time. Even if

apare no great expense practice change

regularly. And make the user worrying about the

safety degrees. This need to proceed suitable

wire ropes in section and grant the

popularization. The inspectors judge the remnant

strength according to precise inspecting

results. Under certain conditions measured this

wire rope breaking pulling force. Master the

real safe coefficient. Not only ensure safe

operating but also determine changing date with

this method. This would benift safe operating

but also determine save the source and utilize

the source effectively. In order to achieve this

aspiration, the keys depend on the testing

method of the wire rope flaw, analysis method

and research and application for the instrument.

The

wire ropes non-destructive testing and

evaluation is that under the non-destructive

wire rope use conditions, determine the wire

rope state characteristic. With the certain

testing technique and the analysis method. And

evaluate their course according to the certain

criterion. The inspector, detecting instrument

and scrap standards are closed together

relation. According to the testing of the wire

ropes results, the inspectors determine the

remaining service life of the wire ropes and

scrap time with the inspectors experience know

ledges for giving judgment upon the wire ropes.

Among them. The testing results of the wire rope

testing instrument is the most fundamental. Only

when obtain the state of the wire rope damage

flaw can evaluate the wire rope. There fore, as

soon as the wire ropes create, the people begin

to research the wire ropes testing problems. The

wire rope non-destruction testing instruments

have been gone out of the laboratory gradually

during the past centennial research. Move toward

engineering application and go further into a

research that is combined with the engineering

application problems. At present, on account of

the continual progress of the wire ropes

manufacturing technique and widespread

application department, demand further research

and developing the testing method and achieving

technique for the wire ropes. This major express

the following several aspects.

Firstly, the rope work wire without proceeding

prestressingtorce processing. When the surface

in the wire ropes happens to broken wire, thus

reveal out of the wire ropes. This is the

obvious, also the most original method—Artificial

visual examination (foreign appellation is

rag-and visual) produce correspondingly. The

Artificial visual examination is proceeding like

this: The inspector stands by the wire ropes and

strokes them with cotton yarn in his (or her)

hand. Testing speed operate for the wire ropes.

If producing the yarn-drawing circumstances, the

inspector stops the location to observe the

broken wire carefully. However, with the

development of the produce technique and

material for the wire ropes, the rope work wire

proceeded prestressing force processing. This

makes the wire ropes to possess the astringency,

without the bedding up words. And with the

people research in a deep-going way for the

geometrical structure parameter and the service

life of the wire ropes, the structure of the

wire ropes become mare and more complex, the

flaw state of the wire ropes become to express

more and more variety and complexity. The flaw

testing difficulty increase continuously. For

example, adopting magnetic focus technique

testing the same diameter of wire ropes, Because

of the fracture magnetic force line distributed

and the fracture geometrical shape complexity,

the signal-to-noise rato (SNR) to the reverse

and the obverse twisting for the wire ropes are

different greatly. The strong signal can be

acquired in the obverse twisting, while the weak

signal can be acquired in the reverse twisting.

Even then it is submerged in the noise of ply

waves. On the other hand, the surface of the

wire rope forms the thicker fat lute for the

wire rope testing.

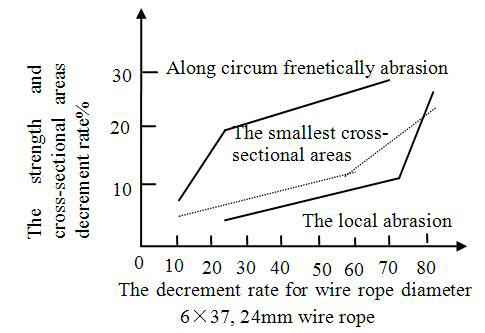

Secondly, the diameter of the rope work wire in

the wire ropes develop from single to various,

from single-layer ply, from circular ply to

triangle ply, and oval-shaped ply. There fore,

the evaluation of the wire ropes flaw must be

also change correspondingly. Take the wire ropes

for example, in form wire ropes with the single

diameter, can evaluate with broken wire numbers

as the target to its intensity. But in the

various diameter obvious. The influence of

intensity is the different between the thin and

thick of the broken wire. Under the

circumstances, it is unreasonable that the wire

ropes state evaluate with broken wire numbers as

the target. Have to find the other target to

wire rope state proceeding evaluation. Thirdly,

the lift system of the wire ropes develops

continuously substitute frictional lifter for

cylindrical drum hoist more and more due to

frictional lifter with the smooth advantage. The

application condition of the wire ropes hare

taken place greatly. The damage state followed

also took place greatly. In the cylindrical drum

hoist system, the wire rope express the bend

fatigue broken wire, while in the frictional

lifter, the wire ropes express the loss of the

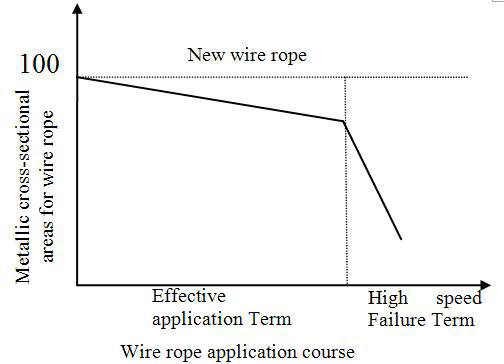

metallic efficient cross-sectional areas. Under

the circumstances, the detecting installation

with the major target for testing broken wire

originally, must consider that how to achieve

testing problems of the wire ropes loss.

Fourthly, with the source decrease increasingly

on the surface of the earth recoverable

reserves, the depth of mineral products

exploitation increases continuously. The length

of wire rope increase continuously, the diameter

of wire rope enlarge continuously, the expenses

of the whole wire rope also increase. This

demand to enhance the safety testing of the wire

ropes, heighten testing efficiency. External

engineers experiment on the fatigue of large

diameter wire ropes. There is evidence that the

wire ropes is easier to occur in internal broken

wire and earlier than external broken wire

frequently. When finding the more external

broken wire, this means that the wire ropes

would be scrapped at once. Under the

circumstances. Because of the visualization can

do nothing about the internal broken wire of the

wire ropes, it is important that the instrument

inspect the wire ropes.

The

fifthly, because of the tourism development, the

ropeway develop rapidly in some touristy

attraction. In order to heighten the ship

passing through speed of the dike-dam, develop

shipping trade important status in the

communication and the requirement of the

communication and transportation trade

high-speed development, the number of the

cable-stayed bridges and suspension bridges are

much more and more. The wire ropes as building

bridge major component safety of their

application would be concerned the safety of the

whole bridge. And because of cable rope out side

cover in building bridge round the antiabrasion.

Put forward a new requirement for testing: In

the early part of the 20th century,

building bridges would be become the application

late period in addition. The requirement to

these bridges would be detected much more and

more.

The

sixthly, in generally speaking under all

circumstances the wire ropes application, the

produce and development of the wire ropes damage

state is a slowly varying course. But in the

course of practice application, discover the

service life shorter, scrap frequently faster

under certain circumstances. The scrap reason of

wire ropes is caused by the parameter

installation unreason-able of the whole lifting

system in this circumstance. For example,

purring the incline wire ropes hoist, if the

intervals between the idler had not been

adjusted inopportune, it would have been caused

wire ropes resonance. To accelerate wire rope

damage. There force, if the inspector can use

instrument, taking change the wire rope testing

results compare with the mystical testing

results. If the inspector discovers the abnormal

phenomena, remind the users for wire ropes

testing lifting system function parameter to

discover the problems and solve them,

immediately. Thus, attain to lengthen the

service objective life of the wire ropes. Adopt

this measures is more effective than application

later period with the instrument testing

lengthen the service life of the wire ropes, and

it is easier to attain scientific application

and arrangement for the wire ropes.

3.

The survey and the forecast for domestic and

foreign. As mentioned before, the wire ropes,

there occur testing problems form their

birthday. After the research and development of

a century, no matter where the testing principle

of the technique achievement, the wire rope

nondestructive testing research produce

development by leaps and bounds. Table 1-1 shows

that the methods and principles adopted once in

the wire ropes non-destructive testing, among of

them, some methods and principles have been

obsolete for the difficulty in technique of

principle. The following is that major introduce

several testing methods that have been used in

the engineering practice and are developed at

present.

(1)

The

Research of the Testing Principle for Wire Ropes

flaw states

The

Research work of this section is the most active

part in the wire ropes non-destructive testing,

also is the keys part.

As

one of the oldest methods, the magnetic

non-destructive testing, it is also the earliest

to apply in the wire rope testing. In 1906, the

south Africa C. Mc Can R.colson developed

together the first wire rope non-destructive

testing installation is on the basis of elector

electromagnetic magnetic principle. After

undergoing the methods of Ac (alternating

current excitation) and DC (direct current

excitation), at the present time, the wire rope

electromagnetic inspection installation become

more and more tend to adopt the permanent magnet

for wire rope the excitation. And technique

maunders gradually. It is also one of the most

widespread application methods at present. The

famous company that produce the wire ropes, such

as NDT Technology Inc, in USA, Meraster in

Poland, their products are all on the basis of

the electro magnetic inspection principle.

In

the wire ropes flaw testing and diagnosing

practice, according to the different nature and

condition of the wire ropes flaws divide them

into two large kinds: LF type (localized) and

LMA type (loss of metallic area). The concrete

character of the two flaws are as follows: LF

type flaw (Localized Fault): in the local

location of wire ropes produce damage that

include internal and external broken wire,

corrosion pots, local shape unusually. LMA type

flaw (loss of metallic Area): produce the

metallic cross-sectional areas in the wire ropes

cross-sectional areas decreasing damage that

include abrasion, corrosion, shrink of the wire

ropes diameter etc. while correspond with LF

type flaw, this kind of flaws change along

radial direction in the wire ropes slowly in

common. The major characteristic that adopt the

wire ropes testing device of the permanent

magnet excitation is that achieve LF testing

passing though local leakage magnetic field

after testing magnetization and that achieve LMA

testing passing through measuring magnetic-flux

change in magnetic circuit arrange sensitive

element. Because of the location difference in

magnetic circuit selected sensitive element,

these testing devices would be divided LMA/LF

circuit magnetic-flux testing method and LMA/LF

major magnetic-flux testing method. In the wire

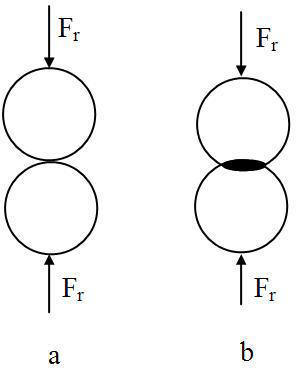

ropes magnetic-flux testing method. Because of

the excitation source and the wire ropes form

close circuit, thus magnetization is easy

relatively. The circuit magnetic-flux and the

major magnetic-flux in the magnetic-flux testing

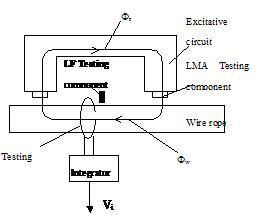

methods refer to Fig1-1 pass through circuit

magnetic-flux

Φr

in the excitation circuit. And the major

magnetic-flux of entering wire. In the LMA/LF

circuit magnetic flux testing, the wire ropes

are magnetized deep and reach the saturation

magnetization with the permanent magnet. Put the

sensitive element between the wire ropes and the

permanent magnet or at certain location in the

circuit magnetic way, measure the magnetic flux

that flow back permanent magnet from the wire

ropes passing through the air internal. This

magnetic flux is the wire ropes metallic volume

function between two pole terminals. The

inspector can measure indirectly wire ropes

average metallic cross-sectional areas between

excitation. In addition, in this testing method,

arrange the other testing devices between two

pole terminals on the neutral surface. Testing

the LF signal. LMA/LF major magnetic-flux

principle in that the wire rope are magnetized

and reach to saturation magnetization. There is

A concentric coil twining round the wire ropes.

(Caused by broken wire, abrasion, corrosion

etc), can lead to change of the major magnetic

flux in the wire ropes. After passing through

the integrator alternate, the output of the

integrator between the major magnetic flux

change proportionally. There fore, only when

measure the change of V1 cans you achieve the

change measure of LMA.

At

present, there two testing methods in LMA;

Because of the bulky volume with the testing

method of LMA/LF circuit magnetic-flux and

radial direction resolving property is lower

(51cm). This method has been obsolete

gradually. While because of the definition

higher of radial direction (4cm) at testing LMA

time with LMA/LF major magnetic-flux method.

Part of LF flaws can also reflect and approach

the wire ropes state evaluation from the

perspective of great practical significant than

the signal of LF is. The signal of LMA is

greater especially; the split coil would be

solved technically. And pass signal-processing

circuit of designing structure unique; achieve

the absolute magnitude measure of the wire ropes

magnetic flux. Make the testing method of LMA/LF

major magnetic-flux extensive application for

the wire ropes in situ testing

Table

1-1 The Wire Rope Nom-destructive Testing

Principle

|

Methods |

Measure Principle |

Expressing pattern |

Advantage |

Shortcoming |

remarks |

|

Solid sound testing method |

Record the longitudinal pulse quantity

when the broken wire occur |

Line of diagram |

Can automatic recording broken wire

continuously |

At present, only apply to the laboratory

the cost of instruction is higher |

It is adopted when the broken wire only

occur |

|

Aeroacoustics method |

Record the acoustic signals, when the

broken wire occur |

Line ditto |

The cost of instrument is lower and can

automatic recording broken wire

continuously |

It is difficult to prevent from the

other influence of disturbance sound. At

present, only apply to the laboratory |

It is adopted when the broken wire only

occur ditto |

|

Artificial visual examination method |

With under 0.3m/s of speed inspect the

surface of the wire ropes |

Without automatic record, analysis

results directly |

A simple easy method and can ascertain

the damage of the surface |

A is waster the time, without object,

science. Grease effect accuracy of

result |

Up to now have been used abroad. |

|

Optical method |

CCD camera shooting head testing the

surface of the wire ropes |

Picture |

Testing accuracy is higher |

The cost of equipment is higher and

influenced by grease |

Detect the diameter. Of the wire rope

successfully |

|

Acoustical method |

Rnock at the wire ropes |

Without automatic record, analysis

results directly |

A simply easy method

|

Measure is unilateral and expressiveness

is poor. |

Major application is that the inspector

evaluation corrosion of the wire rope |

|

Machinery method |

Determine the resilience of the wire

ropes loading and length with testing |

Data |

|

Both exerting stress and length are

difficult to master accurately |

|

|

Magnetically method |

Determine the leakage magnetic-field |

Line of diagram |

Can determine the broken wire, corrosion

sopot, distortion |

When the corrosion, abrasion, broken

wire come into existence at the same

time. It is difficult to distinguish

them |

At present it would be mature md use

abroad. |

|

Measure the major magnetic-flux |

Ditto |

Can determine the change of metallic

cross-sectional areas for the wire ropes |

Can’t suit testing broken wire

|

Ditto |

|

Magnetically imagery |

Picture |

Can orient ate broken wire, corrosion

area accurately |

The structure is complex and the picture

explanation isn’t unique |

At present only apply to the cob

oratory |

|

x-ray |

|

Take a photogram |

Can know broken wire accurately |

The cost of protective installation is

higher. And can’t measure continuously

for long time exposure |

|

|

Methods |

Measure Principle |

Expressive pattern |

Advantage |

Shortcoming |

Remarks |

|

Sonic launch method |

Determine wire rope launching supersonic

waves when wire rope structure take

place changes |

Tran audient analysis |

|

The cost of instrument is big her, can

only use in the quiescent load part

|

|

|

Supersonic method |

The supersonic wave disseminate in the

mediums |

Reflect gram |

|

Can’t reflect the wire ropes state in

detail with existing reflect of every

wire rope |

|

|

Magneto striation method

|

Magnetostrictive effect

|

Line of diagram |

Non-cross block measure, can inspect

within 100m, the flaw of the wire ropes

for once. |

The definition and detection rate is

poor for small fracture and flaw change

|

|

|

Electrical eddy-current method |

Electrical eddy-current effect |

Ditto |

Can inspect broken wire, fracture,

corrosion in the wire ropes |

Tendency surface effect in fluence the

broken wire testing. The signal to noise

rato (SNR) is lower. |

|

|

Electrical current method |

Determine ohm age of fixing wire rope

length |

Line of diagram or data |

Can ascertain fracture surface state |

It is difficult to master the end

stress, temperature and prolongation for

the moving wire ropes |

|

|

Vibration testing method |

Transversal excited vibration waves

dffeminate in the wire ropes

|

Lin of diagram |

Can inspect the change area of cross

sectional area for the wire ropes |

Flaw definition poor |

|

In LF

testing, at first, adopt the inductance coil

testing leakage magnetic field in the wire

ropes. But because the output signal in coil

come under the influence of relative speed

change between the wire ropes and the coils

greatly. This testing method has been obsolete

gradually. Because of the development of the

semiconductor technique, Magnograph series

sensors in Canada, at first, adopted hall device

inspect the leakage magnetic-field and applied

for a patent in the late seventies Canadian

rotes co graph sensor adopted the fluxgate

technique achieved the signal collection of the

wire rope LF flaw for avoiding violate patent of

Magnograph in the ignites. Domestic technique,

middle China science and engineering university

and Shanghai mercantile marine institute adopted

the integrated hall device and the fluxgate

achieved the signal attainments of LF flaw

individually.

Whether the circuit magnetic-flux inspect or

whether the major magnetic-flux of LMA/LF

inspect, if you want to require the flaw

information for the wire ropes, the wire ropes

must pass through the sensor. This cause wire

ropes whole course testing to be difficult to

achieve. In order to solve this problem, in

1994, H.K wan and C.M Teller at American

Southwest Research put forward a kind of new

type wire ropes flaw testing sensor that is on

the basis of Magnetostrictive effect

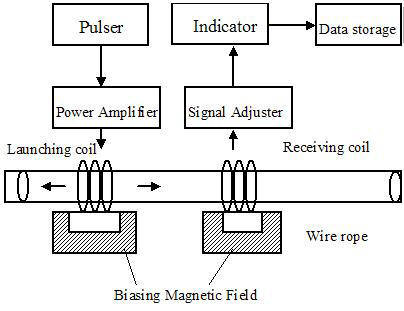

(Magnetostrictive Sensor, Mss) The basic testing

principles, as shown in Fig 1-2 (8)

Each

sensor includes a permanent magnet and a

inductance coil. The permanent magnet provides a

biasing magnetic field to ensure the sensitivity

of sensor and electric is the same with

mechanical wave spread along the wire rope axial

direction. After the launching coil is

stimulated by the pulse signal with the Pulser,

the joule effect productive wave would spread

along the wire rope axial direction. When the

mechanical wave pass through receiving coil,

because of villain effect. If there occur flaw

signal, receiving coil can accept the return

waves of flaw signal. In this way can achieve

the wire ropes flaw testing. Because of existing

initiative testing method, the time is shorter.

The effectiveness is higher. According to the

two scholars tentative experiment, testing 100m

length wirer ropes need only several seconds.

At

present, have the major difficulty in the

following two respects for this testing method: At

present, have the major difficulty in the

following two respects for this testing method:

(1)

The

Difficulty in Physics Field,

Nowadays don’t make a deep research on the

mechanical wave mechanization of

Magnetostrictive effect creation and trans

missive characteristic.

(2)

The Difficulty in Technique

According to the tentative research results. It

is very wide that the Magnetostrictive effect

causes the signal frequency band from several

KH2 to 1m. How to collect this signal is that

practical application must be solved the

problem. If the two tough jobs were broke, this

would be had a great future testing method.

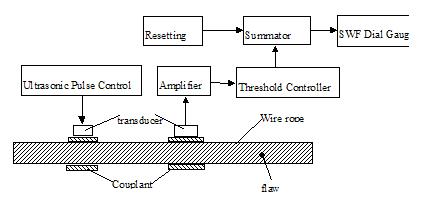

At

abroad, the Acousto-ultrasonic method is being

adopted to achieve for the wire rope state

testing on line. Now (9.10.11.12) besides the

magnetic testing method. The basic testing

principle ad shown in Fig. 1-3

The

method is development on the basis of the

original sonic launch method. Lead the sonic

into wire ropes with a group of transducer,

couplant. The imitative sonic launching specific

property transmits in the wire rope. The other

group of, conplant collect the signal, after

passing amplifier enter the threshold controller

and then calculate the stress-wave factor (SWF).

Because of comprehension with sonic launch and

ultrasonic two methods. Not only can proceed to

the flaw inspection, flaw imagery, and flaw

characteristic, but also can evaluate the

inherent function of the testing wire ropes

online. Such as the fatigue loss, intensity,

hardness etc, for wire ropes.

This

method can have application in dynamic state

wire rope testing. It overcomes that the sonic

launching method can only have application in

static state wire rope testing and catch the

instantaneous signal of the broken wire

breakage, without enough.

Above-mentioned methods have main application in

the material function of wire rope testing. At

present the all of the world, are proceed to

research the geometrical deformation of wire

ropes loose ply testing etc. German SPK Company

try to adopt the CCD device testing the diameter

of the wire ropes. For the change of the wire

ropes. American adopt artificiality knock at the

wire ropes with hammer in their hands to

discover the loose ply flaw.

(2)

The

Analysis Process for Wire Ropes flaw Signal

After

the flaw signal of wire roper is colleted by the

sensor with the certain principles and methods.

The analysis process measure of signal is also

very important. The simplest method is that to

show the signal on the oscilloscope. But is

can’t store to provide analysis application

later. In order to over come this flaw, can

adopt the notebook recording instrument or tape

recording instrument. The wire rope testing

instrument of earlier period adopted all these

methods such as Magnograph and LMA series flaw

detector. Up to the eighties, with the

high-speed development of the computer technique

and digital handling technique, the

computerization and visualization of the testing

instrument the came a development tendency. With

the signal of the wire rope testing processing

because of the signal of LMA and LF existing

different testing principle and signal

characteristic, the signal processing adopted

the different technique. In 1978 at Poland,

researcher carried out experiment research,

adopt three testing circuit, to collect the

signal of the wire rope cross0sectional area

loss, and then after passing A/D transform,

achieve the digitalization.

According to the establishing model calculate

the cross-section of the wire rope loss and chi

splay on the computer’s screen. First of all a

chi eve the quantitative handling. The domestic

technique, Middle China science and Engineering

University achieved the quantitative testing of

the wire rope broken wire numbers, in the

eighties. With the adopting equally spaced

interval sampling technique and differential

super threshold algorithm. In 1995 Japanese

scholar Koichi Hana Sake and Kazuhiko Tsukada

introduced image formation technique into the

signal handling of the wire ropes. At first

achieved the visualized testing of parallel wire

rope broken wire.

American, Doctor H.R. Weischedel combine with

the worksite application condition to the signal

testing of LMA. Testing the signal size of wire

rope LMA within the speed limits has nothing to

do with the operating speed for the wire ropes

with designing the split coil and the electric

circuit structure of the new and original

structure. And adopt a certain calibrating

pattern achieve the quantitative testing of LMA.

In Poland, K,Zawada introduced the personal

computer Memory Card Internatonal Association

(PCMCIA) standard in to the manufacturing

standard of the wire rope testing instrument.

Because of the high reliability, antimagnetic,

powerful applicability, provide a way for the

wire ropes testing instrument toward engineering

application. At present, in Poland, MD series

wire rope inspection instrument inter face in

Meraster Company, all adopted this standard.

(3)

The standard of the Wire Ropes non-destructive

Testing evaluation and the Instrument Testing

It

includes the contents of the two sides, one is

the testing signal evaluation, the other is that

it evaluates the wire ropes states for the

testing results; evaluation of the testing

signal is also evaluation for the testing

instrument. It includes the index of the

instrument definition, quantitative definition,

penetrating power; signal-to-noise rato of

testing signal is lower. Can’t be quantitative

testing ability. After leading to the computer

technique, achieve the quantitative analysis and

handling for the wire rope flaw signal. At

present, because of the wire rope quantitative

testing technique mature day by day, and the

results of testing can be evaluated for the wire

rope state. Because of the wirer rope state

evaluation is major evaluating the intensity of

the wire ropes. But existing testing instrument

can’t test the intensity of the wire rope

directly. Because of the results of testing are

related to the scrap standard of the wire ropes

frequently. It is often necessary to introduce

the personal factor, to the wire rope inspector

is familiar with the instrument function and

applied state.

At

present, the scrap standard of the wire ropes

make on the basis of breaking stress for the

wire ropes. But mechanical function research of

the wire ropes express this method unreliability

in resent years. There fore, according to the

present scrap standard of the wire rope with the

results of testing, evaluating method to the

wire ropes state become more and more

unreliable. American NDT Technology Company is

on the basis of the wire rope inspecting

installation of LMA-LFTM type,

combine with the worksite application condition

in the installation and the Artificial visual

examination results. Put forward now to

evaluating the method of the wire ropes

intensity.

American inspection and material Association

worked out the Electromagnetic Examination

Standard of Ferromagnetic material steel wire

rope (E 1571-96) in 1997. this is symbolic of

the testing and evaluation have enter a brand

new stage for the wire rope.

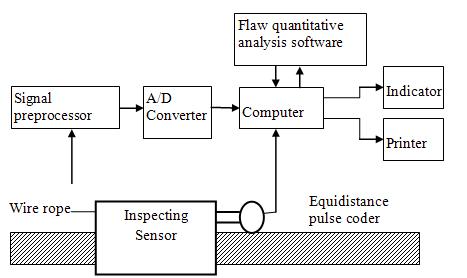

2.

The constitution for the wire ropes inspecting

installation

According to the peculiarity in coalmine

application, the basic principle of the testing

wire ropes adopts the magnetic non-destructive

testing method. There is inspecting sensor,

signal preprocessor, analog digital converter,

sampling controller, computer analysis handling

system etc several main component parts in major

inspecting installation. The basic block diagram

as shown in Fig. 2-1

Fig.

2-1a Wire Rope Flaw Testing System for Three

Gorges Ship lift

The

sensor adopts two different magnetic testing

methods inspect the broken wire and the loss of

the cross-sectional areas for the wire ropes.

Among them, broken wire testing sensor would

export two way-signals individually. The signal

is alternating current signal. Connect

alternating current signal amplifier. The sensor

of the cross-sectional areas loss testing would

export two way-signals individually. The signal

is direct current signal. Connect direct current

signal amplifier later, multiple-path different

nature signals pass through A/D converter later

with computer, proceed to proceeding to

analyzing handling, controlling sensor signal

sampling is sampling controller. According to

the sensor relevant wire rope operating length

send out sampling pulse, control to sample the

output signals of the two sensors individually.

Among them, interspaced of broken wire signal

sampling is less than the signal of the diameter

testing. While the signal of the diameter

testing is less than testing signal of the

cross-sectional areas loss. It is between from

1mm to 10mm in general.

The

following is that introduce the testing system

combining with the main technique difficult

point.

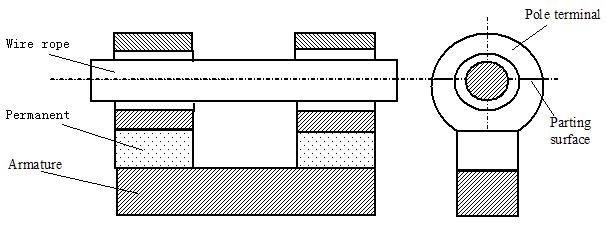

(1)

Development of the sensor

① The

Magnetic problems for wire ropes

According to the knowable technique as analyzed

before, adopt the magnetic testing method

inspect the same time, with the development of

the permanent magnet material, adopting the

smallest volume permanent magnet can put forward

very strong magnetic field to be satisfied with

the necessity of wire rope magnetization. There

fore, testing wire rope method become more and

more tended to adopt the permanent magnet

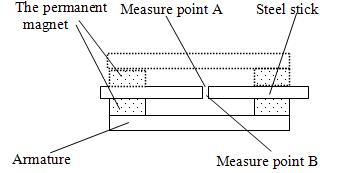

achieving wire rope magnetization. Fig. 2-2 is

that adopt the magnetic circuit in the small

diameter wire rope testing. Because of smaller

diameter for wire rope, the magnetized volume is

smaller, correspond entry. At the Sam time.

In

order to ensure the wire ropes magnetic

uniformity, take increasing pole terminal method

between the wire ropes and the permanent magnet,

on the other hard, can also adopt method to

parallel with the multi-piece permanent magnet.

Increase magnetic flux in the wire ropes;

achieve the wire ropes magnetic requirement. In

face, adopt circumferential single circuit axial

magnetization for wire ropes. Because of each

circumferential part for the wire ropes being

different from the permanent distance, the

magnetization for wire ropes is non-uniform.

Near the permanent magnet parts magnetic field

intensity is higher, on the opposite side parts

magnetization degree is lower in general. In

spite of the pole terminals were adopted, can

decrease this non-uniformity in certain degree.

With the enlargement of the wire rope diameter,

the non-uniformity distributed of the magnetic

field become more and more obvious under the

extreme circumstances, near the permanent magnet

parts can inspect the signal obviously. On the

opposite side parts can’t inspect the signal.

There fore, to large diameter wire rope

magnetization can’t adopt single circuit

exciting way, must adopt circumferential

multi-circuit axial exciting magnetization way

manly. Because of the nonlinearity and vector

characteristic for magnetic field, the magnetic

intensity in the wire ropes can’t increase after

the multi-magnetic field superimposition. There

fore, when designing magnetic circuit, must

distribute magnetic circuit reasonably. Ensure

the multi-circuit magnetic effect. In the

initial stage of experiment, have application in

double circuit for small diameter wire rope

proceeding excitation in imitation of single

circuit excitation way. With the result that

instead of increasing, the broken wire of the

wire ropes even decreasing. And the signal is

instability. These phenomenon express the

multi-circuit magnetization can’t design in the

light of the single circuit magnetic way simply.

This is conforming to the theoretical analysis

as mentioned before. At present, the key problem

is that find the reason that the magnetic line

distribute the magnetic circuit aspect. In

order to ensure the wire ropes magnetic

uniformity, take increasing pole terminal method

between the wire ropes and the permanent magnet,

on the other hard, can also adopt method to

parallel with the multi-piece permanent magnet.

Increase magnetic flux in the wire ropes;

achieve the wire ropes magnetic requirement. In

face, adopt circumferential single circuit axial

magnetization for wire ropes. Because of each

circumferential part for the wire ropes being

different from the permanent distance, the

magnetization for wire ropes is non-uniform.

Near the permanent magnet parts magnetic field

intensity is higher, on the opposite side parts

magnetization degree is lower in general. In

spite of the pole terminals were adopted, can

decrease this non-uniformity in certain degree.

With the enlargement of the wire rope diameter,

the non-uniformity distributed of the magnetic

field become more and more obvious under the

extreme circumstances, near the permanent magnet

parts can inspect the signal obviously. On the

opposite side parts can’t inspect the signal.

There fore, to large diameter wire rope

magnetization can’t adopt single circuit

exciting way, must adopt circumferential

multi-circuit axial exciting magnetization way

manly. Because of the nonlinearity and vector

characteristic for magnetic field, the magnetic

intensity in the wire ropes can’t increase after

the multi-magnetic field superimposition. There

fore, when designing magnetic circuit, must

distribute magnetic circuit reasonably. Ensure

the multi-circuit magnetic effect. In the

initial stage of experiment, have application in

double circuit for small diameter wire rope

proceeding excitation in imitation of single

circuit excitation way. With the result that

instead of increasing, the broken wire of the

wire ropes even decreasing. And the signal is

instability. These phenomenon express the

multi-circuit magnetization can’t design in the

light of the single circuit magnetic way simply.

This is conforming to the theoretical analysis

as mentioned before. At present, the key problem

is that find the reason that the magnetic line

distribute the magnetic circuit aspect.

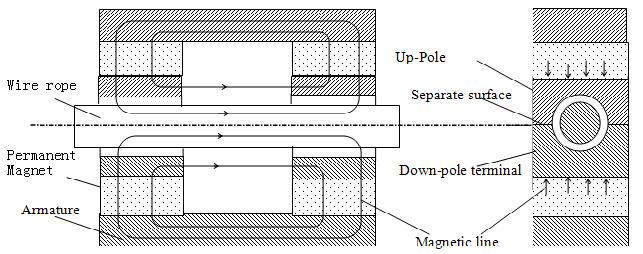

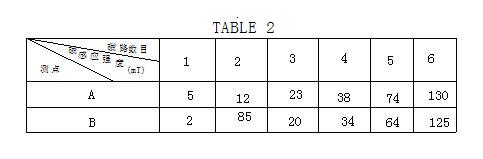

When

analyzing to adopt double circuit magnetization,

the magnetic line distribute as shown in Fig.

2-3 Because of existing the pole terminals,

couple up magnetic line of up and down two

magnetic circuit with the pole terminals, form

the magnetic line of the certain direction

concentrating pole terminals areas. It becomes a

magnetic source that forms the magnetic line

with armature closing up on the other end

surface magnetic line. At the same time, in

order to ensure the wire ropes magnetic

uniformity. The volume of the pole terminals is

larger generally. In this way, the pole

terminals is magnetized by the permanent magnet

providing a great deal magnetic power, not by

the wire ropes. In order to achieve the

multi-circuit magnetization it is impossible to

increase (or decrease) the volume of the pole

terminals between the wire ropes and the

permanent magnet.

In

order to test and verify the correctness of

above-mentioned analysis, proceed with

experiment.

1) At

first, make an experiment on a 24mm diameter

steel stick the experimental installation as

shown in Fig. 2-4. At first, adopt single

circuit excitation. Detecting magnetic induction

intensity’s are all 0.48T in measure point A,B

individually. And then add as shown in dotted

line excitation circuit. The whole system forms

a double circuit excitation structure. At that

time, detecting magnetic induction intensities

are 0.73T and 0.75T in measure point A,B

individually. This express that increasing

magnetic circuit can be heightened magnetic

intensity in the magnetic stick. During

proceeding with sensor structure design, it is

impossible for us to adopt magnet adjoining

steel stick structure way. There must be a

distance between magnet and steel stick. In

order to imitate this condition, at first as

shown in Fig.

The

magnetic circuit of active line. Add a 5mm

thickness aluminum plate because of

non-permeability magnetic material. At that

time, detecting magnetic induction intensities

are 0.69T and 0/74T. Obviously, it is unlike for

you to imagine the magnetic induction

intensities of A point is mare than B point,

even if the magnetic inductor intensities of

these two measure points are all decreased.

After adding a aluminum plate in dotted line

magnetic circuit, detecting magnetic induction

intensities are 0.66T and 0.67T individually.

Even if after adding the distance between magnet

and steel stick, the magnetic intensity is

decreasing. But it is still more power than

single circuit magnetic intensity. In addition,

increment of magnetic circuit they exist the

nonlinearity and vector characteristic, we can

find the change condition from the whole

magnetic induction intensity of magnetic circuit

measure point. This require us to design the

magnetic circuit must pay attention to have a

subtle difference between the magnetic circuit;

otherwise it is easy to lead to magnetic circuit

design failure.

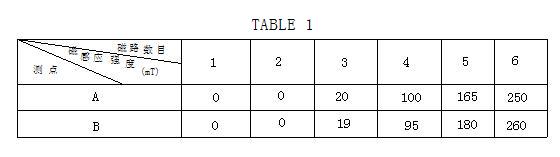

2) In

experiment 1, we consider only magnetic circuit

symmetrical condition; consider the non-symmetry

condition in the following. In the laboratory,

make an experiment on a 90mm diameter steel

stick. Experimental installation as show in Fig.

2-5. during the experiment, add the condition of

magnetic circuit as show in order number, detect

experimental data as show in table. After adding

a 5mm thick ness aluminum plate in excitation

circuit, detect experimental data as show in

table2.

Fig.

2-5

Φ80mm

steel stick magnetic Experiment Installation

Make

out from the experimental data of table 1 and

table 2: To large diameter of steel stick,

muti-circuit excitation can increase magnetic

intensity obviously. Whether the wire ropes from

above mentioned experimental scheme is employed

or not, still test and verify with experiment.

According to the above-mentioned structure

design sensor make a magnetic intensive

experiment or 52mm, 90mm diameter for the wire

ropes. With the result that the magnetic

intensity of the wire ropes testing. The

above-mentioned experimental express that it is

feasible to adopt the circumferential

multi-circuit axial exciting magnetization.

②

The

acquirement for broken wire signal of the wire

ropes

1)

The

difficult point for broken wire signal

acquirement

The

exciting installation magnetizes the wire rope

to certain magnetic field intensity; adopt the

permanent magnet as exciting source. Leakage

magnetic testing installation inspects the

broken wire producing diffusive leakage magnetic

field. There are inductance coils, hall device,

magneto sensitive transistor etc, application in

the magneto sensitive testing sensor of this

kind magnetic field testing.

When

the induced coil test, induced output voltage

changes with Cole scanning speed change. The

temperature drift of magneto sensitive

transistor effect is greater; there fore the

hall device for Hall effect is more advance in

testing this kind of magnetic field. The

inspecting sensor is composed of exciting

installation and leakage magnetic testing

installation when testing the wire ropes, must

consider the following three questions:

(a)

According to leakage magnetic field testing

principle of the wire rope broken wire, can be

knowable for the single piece of wire rope

diameter is thicker in 6×7

structure wire rope. At that time, the broken

wire signal is easy to obtain for the single

piece of wire rope produce the leakage magnetic

field growth. But according to the experiment,

the distances between strand peak and strand

wave is growth as the wire rope diameter

increase. And the relative location between the

wire rope strands is easy to become deformed, as

the wire rope diameter increase. As a result

cause that the broken wire signal is very easy

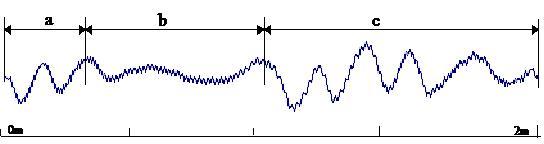

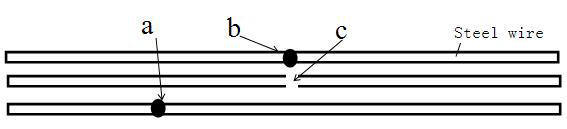

to inundate with the strand wave signals. Fig.

2-6 is the strand wave signals of 6×7

structure wire ropes. In Fig. Section a and

section is normal strand wave signal, section b

is that the signal form with the wire rope ply

strand and the distance growth between wire

strands. Besides, there is a burr signal in the

signal cu. This is formed with the leakage

magnetic field between the wire ropes for the

diameter of the wire ropes.

(b)

In order to ensure no miss testing, must install

multiple component along the wire rope

circumference for the diameter of wire rope

growth and the circumferential covering area

limited of the single component installing

component number can be calculated as follows.

wire rope length

Fig 2-6 Wire rope

stock wave signal

Where Sp is the perimeter of component

arrangement ring,

Ss is the circumferential covering length of the

single component

CINT[·]

is round off number

According to the circumferential covering are

length is 7mm, if the diameter of wire rope is

30mm, must arrange at least 14 components along

circumferential direction can achieve no missing

the testing. As that time adopted the single

component handling, it was very complex.

(c)

The wire rope fracture out diffusion leakage

magnetic field intensity attenuate from fracture

location out ward as space negative index. There

fore, the magneto sensitive component can

inspect the internal broken wire intensity very

weak. On the other hand, the broken wire in

inlayer produce the magnetic field to become

weaker for outer wire rope screening effete.

2)

Magnetic Focus Testing Technique

In

accordance with the above-mentional character,

the broken wire testing in view of the magnetic

focus testing technique, inspect the leakage

magnetic field in the different adecker wire

rope broken wire creating leakage magnetic

field. The magnetic focus testing principle is

as shown in Fig. 2-7

The

magnetic focus ring of uniform-distillated

circumference collects the Hall device making

hall device detecting average magnetic field

with in the following four points mainly:

(a)

the magnetic focus ring adopt the high

permeability materials manufacture, such as

industrial clean iron, perm alloy. They collects

weak magnetic field with the wire rope fracture

creating out diffusion circumference, increase

the testing sensitivity. The experience express,

the sensitivity can heighten over 10 times as

compared with single Hall device testing.

(b)

In order to prevent from missing testing, it is

necessary to arrange a great deal components

along circumference usually for the single Hall

device scanning areas are limited along wire

rope circumferential coverage. This wand

increases the complexity in detecting sensor and

follow-up signal handling system. After adopting

the magnetic focus ring, would enlarge the

scanning range of single component. There fore,

using few components such as two or four can be

achieved the no missing testing for the leakage

magnetic field.

(c)

There occurs homogeneous influence in the

magnetic focus ring toward magnetic field. There

fore after adopting the magnetic focus ring,

would homogenize the leakage magnetic field

between the wires and strands in the wire ropes

to heighten the sound-noise rate of the testing

signal.

(d)

Arrange the each magnetic focus ring with a

piece of Hall deice, and a piece of Hall device

deals with independent channel. Thus, can

distinguish the broken wire in the different

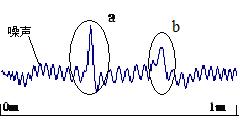

locating and layers. As shown in Fig. 2-8, adopt

the above-mentional testing method detecting the

output signal curve on the surface of wire rope

and the certain channel in the internal core

wire broken wire testing. In the Fig, a,b

location is the signal curve of a piece of outer

broken wire and a piece of internal broken wire

individually.

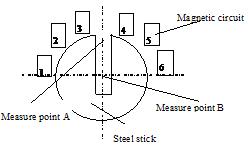

Magnetic bridge

circuit equivalent magnetic circuit model

③

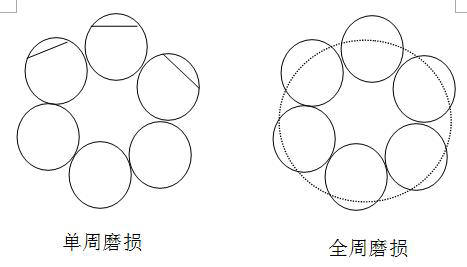

The inspecting method for abrasion signal

Under

the ordinary circumstances, the abrasion testing

of the wire rope adopt the testing main

magnetic-flux method. The testing component

adopt testing coil unusually. This brings the

two problems for wire rope testing in situ.

1)

The trouble of the sensor installation is caused

by the coil twining the wire rope.

2)

The sensitivity of testing coil is relevant with

the operating speed of wire rope relative to the

coil. Adopting the Hall-device testing magnetic

field possess the advantage without speed

influence. And can acquire absolute magnitude

for the magnetic field. But, when the Hall

device was put in magnetic wire rope main

magnetic circuit testing directly, the Hall

device output signal the saturation wouldn’t be

susceptible to the tiny change in magnetic field

for the magnetic inductive intensity great (in

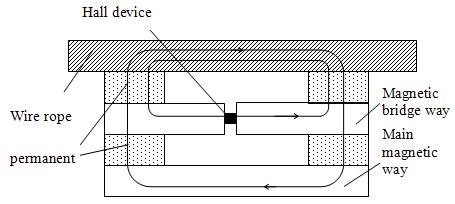

general from 0.6T to 1.0T). for this reason, put

forward utilizing the inspection principle for

magnetic bridge circuit magnetic way, place the

Hall device in magnetic bridge way, testing the

tiny change for the magnetic inductive intensity

in the balance point, (the magnetic inductive

intensity is with in

±100mT

in common) to ensure Hall device high

sensitivity and linearity. The basic principle

as shown in Fig. 2-9.

The

main magnetic way and the bridge way combine

action magnetizing the wire rope to reach the

saturation degree. Because of the wire rope and

the main magnetic way being symmetrical about

magnetic bridge way, can’t consider the

influence of leakage magnetic flux. According to

kirchhoff principle for magnetic circuit. This

is,

Φm=Φw+Φb

(2-2)

WhereΦb

is the magnetic flux in the magnetic bridge

circuit

Φb=BbSb

among them,

BbSb

are magnetic inductive intensity and

cross-sectional areas in magnetic bridge way

individually:

Φm

is the magnetic flux in the main magnetic way.

Φm=BmSm

among them,

Bm,

Sm

are magnetic inductive intensity and

cross-sectional areas in the wire rope,

Φw=BwSw,

among them,

Bw,Sw

are magnetic inductive intensity and

cross-sectional areas. In the wire ropes, take

above-equation substitute (1) after arrangement,

obtain the equation we may write the equation.

Sw=(BmSm-BbSb)/Bw (2-3)

Here,

the magnetic inductive intensity

Bw

in the wire rope and the magnetic inductive

intensity

Bm

in the main magnetic circuit are constant value

near saturable magnetic degree. The

cross-sectional areas for the main magnetic way

Sm are decided by design. There fore, make out

from the equation (2-3) the cross-sectional

areas of the wire rope Sw and Bb related to

linearity.

Under

the ordinary circumstances, the wire rope is

identical with magnetic field parameter in main

magnetic circuit; through the magnetic flux in

magnetic bridge circuit is zero. When the

cross-stctional areas for the wire rope change,

the balance of the whole magnetic circuit system

is broken. The magnetic flux in the bridge way

isn’t zero. After testing Bb, the

cross-sectional areas Sw can be acquired from

equation (2) calculation. The Fig. 2-10 Sw is

given by the following. Technique.

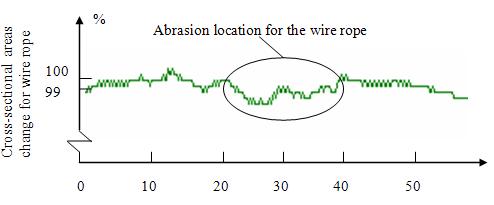

Fig 2-14Software system diagram Fig 2-14Software system diagram

Adopt in this prinuple designed sensor collect

abrasion signal curve of wire rope in the

certain mine lifting wire rope

(2)

The handling electric circuit for detection

signal

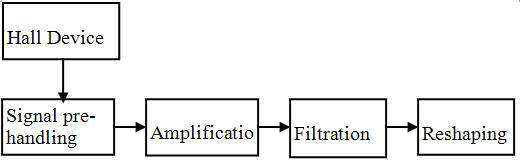

①

The pre-handling electric circuit for detection

signal

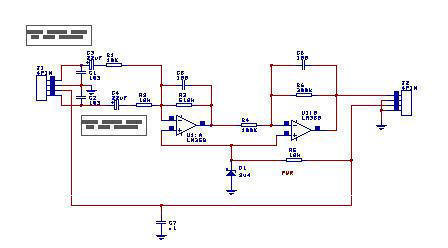

The

electric circuit principle is shown in Fig.

2-12, the electric circuit principle is shown in

Fig.2-13

The

electric circuit is composed of the signal

coupling, amplification, low-pass filtration and

reshaping etc. link.

In

order to restrain the work electrical power

disturbance in worksite situ, the electrical

power of signal handling installation adopt the

supply power pattern with PC/DC second regulated

power supply voltage stabilizer to heighten the

sound-noise rate and stability of detection

signal. The signal handling circuit possesses

the function as follow.

1)

Can pick up the weak signal that the testing

component sends from the noise background, the

sound-noise rate for testing signal is over

34dB.

2)

Can handle the multichannel-testing signal, each

handling channel for testing signal doesn’t

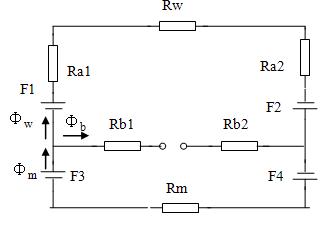

disturb each other.

3)

Every channel can adjust the zero drift of

amplifier and the gain of the amplifier.

4)

Can adjust pass band in wave filter.

③

Data

sampling board Selection

The

function of A/D trans form is that the sensor

with pre-handle send the analogue signal

changing the digital signal of available

computer handling to achieve quantitative

analysis of flaw providing foundation. When

choosing A/D, must consider the precision and

time of trans form, channel number etc. Here,

after consideration every aspect factor, select

the PCL-818C A/D board of Taiwan Yanhua company

Products. The A/D board is on the basis of IBM

PC/XT/AT or data sampling board with

high-function multifunction in compatible

machine. It is possessed of feature as follow.

1)

Can select 16 channels single-ended or 8

channels double-ended

2)

Analogue quantity input

The

twelve-digit number A/D trans form precision

adopt DMA when data Tran missive pattern of

different amplificative gain, the single channel

sampling frequency can use 40Khz.

3)

The software programming can adjust the multiple

of gain.

4)

The software can install A/D quantity size

5)

Provide trigger of the software, internal clock

and outer A/D Tran missive pattern

Besides, the A/D board can connect the PCLD-8115

signal adjustable board with Yinhua company

products. The signal adjustable board provides

temperature compensation circuit can restrain

temperature drift for signal influence

(3)

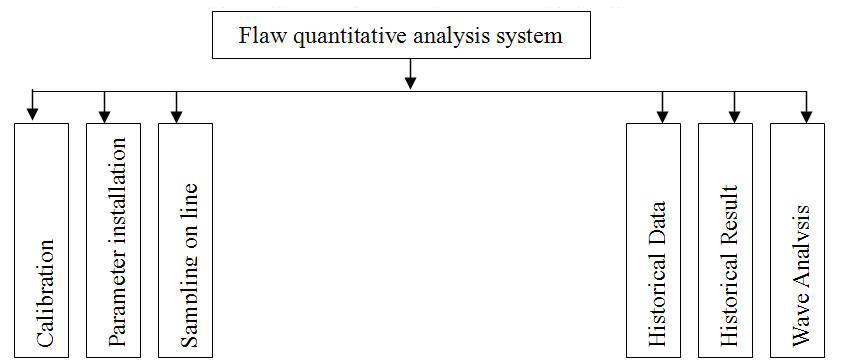

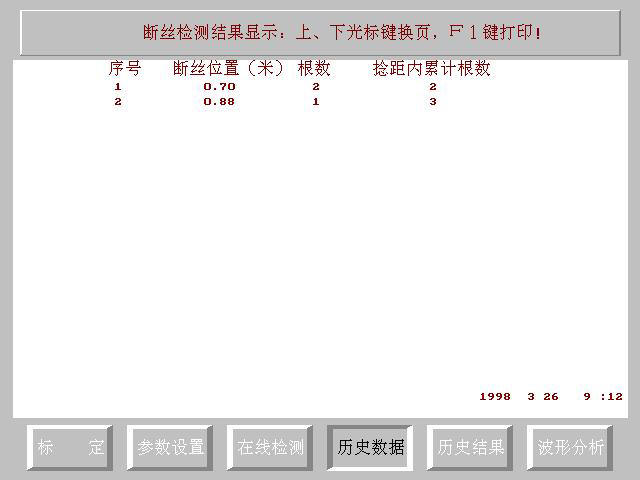

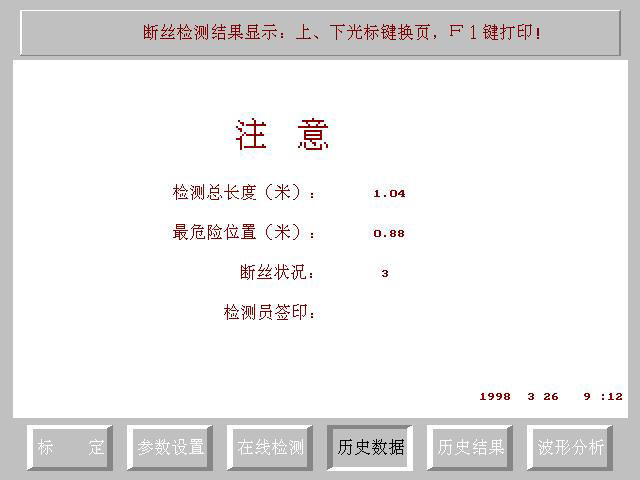

The development of analysis software for signal

quantity

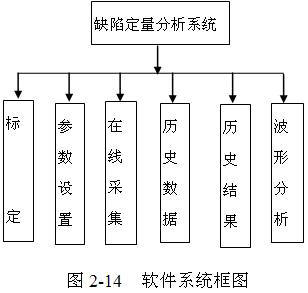

.The

software block diagram for the wire rope flaw

quantitative analysis system is as shown in Fig.

2-14 parts of function brief introduction as

follow.

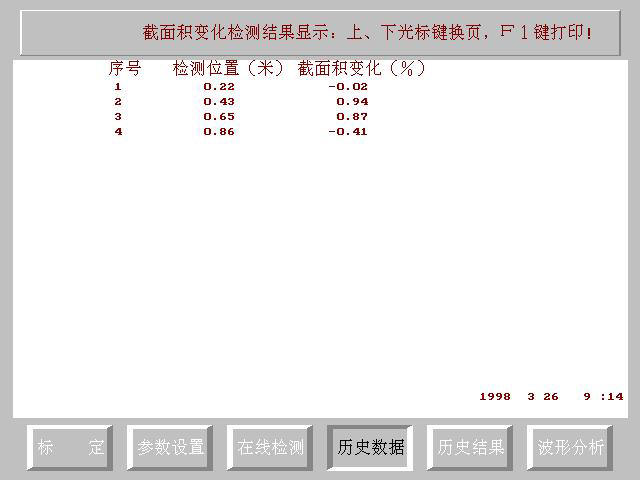

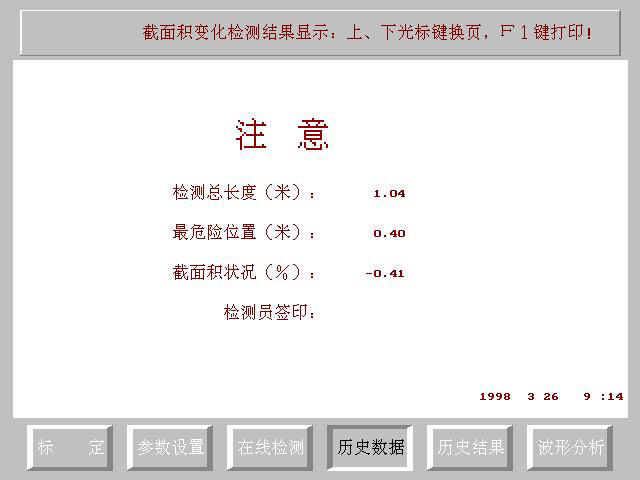

Calibration

——testing for broken wire. Ascertain threshold

value.

Achieve the quantitative analysis

for wire rope broken wire.

Parameter

installation——Provide different structure wire rope parameter

and the

Quantitative analysis required parameter.

Sampling

on line——When the sensor moves along the wire rope, the

optical code

Wheel

sends the outer-triggered signal; take the

signal of the sensor into the computer,

Achieve space sampling for the testing signal.

Ensure the quantitative analysis.

Historical

data——Proceed to analysis offline for sampling signal

in the past

Historical

result——Proceed to display again for analysis results in

the past

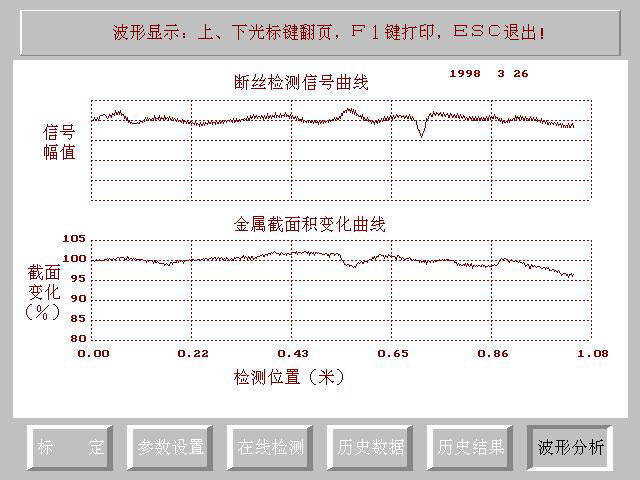

Wave

analysis——Proceed to wave display for sampling signal,

under this state,

pushing the key F, can print the displaying

wave.

Fig.

2-14 software system Block Diagram

②

The quantitative analysis for abrasion flaw

According to the magnetic bridge circuit testing

principle, can know that the metallic

cross-sectional areas for the wire rope Sw is Sw=(BmSm-BbSb)/Bw,

there fore, after the sensor inspect Bb, the

cross-sectional areas of the wire rope Sw can be

get from above equation.

The

abrasion of the wire rope is corresponding with

the change quantity of magnetic flux. In fact,

it is absolute change in whole magnetic flux of

magnetic circuit variance. With above

theoretical analyses can know that it is

relevant with in proportion between the abrasion

quantity and signal amplitude of wire rope. In

order to ensure the sensor in the course of

practical testing, possess the testing areas as

large as possible, for the component is liner

with out put in

±100mT.

At the sensor design stage, would ensure

magnetic feature in the main magnetic circuit is

consistent with magnetic feature in wire rope

testing soon. This means that make the

magnetic-flux near zero passing through balance

magnetic circuit. The metallic cross-sectional

areas of the wire rope change very great for the

different structure and technology of wire rope.

Proceed to influence very great for magnetic

circuit feature of the whole testing

installation. The testing result isn’t accurate.

There fore, before testing the wire rope, must

calibrate the sensor. Namely, put the new wire

rope without abrasion, into the sensor. The type

of this wire rope is consistent with the

diameter, material etc. Of testing wire rope.

During the operating course, unload change,

stretcher strain deformation have influence on

the cross-sectional areas of wire rope for the

wire rope is a elastic component.

It is

require that the testing installation must

calibrate testing online. Developed inspection

installation provides two different calibration

methods to counter different application state.

After the whole lifting system install adjusts,

proceed to testing for new wire rope testing

online. There fore, select at time, testing

result is compared with the basis point to

acquire the state of wire rope relative

abrasion. In general speaking, adopt the

preceding method is more accurate to acquire the

abrasion state of the wire rope.

Besides, the abrasion testing of wire rope is to

measure the absolute intensity of magnetic field

in the magnetic circuit in fact. The measuring

is each point abrasive size actually. The

leakage magnetic field has great influence on

testing result for the deformation and the

broken wire. For this reason, must adopt the

smoothing technique in software to decrease the

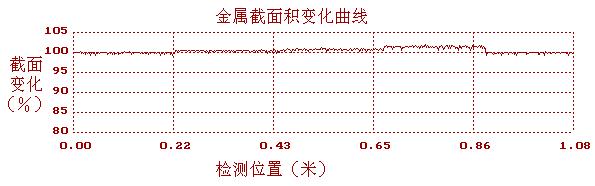

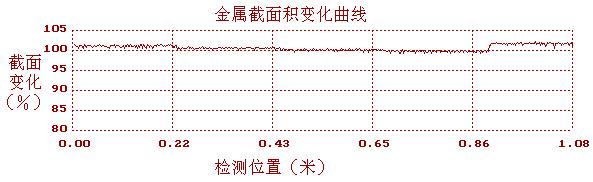

influence of abrupt change leakage magnetic

field. The Fig from 2-16 to 2-18 is the

quantitative output results for abrasion

testing.

③

The quantitative testing for rustiness

The

rustiness for wire rope can be divided into two

kind of pitting and corrosion. The rustiness

leads to the decrees of the efficacious metallic

cross-sectional areas. Not only breaking load

would decrease, but also fatigue occurs

untimely. Obvious for the fragility being

coursed by stress crack. Rustiness can also

decrease the elasticity for wire rope. At

present, the quantitative evaluation for wire

rope rustiness lacks the effective means. Here,

we are on the basis of the basic principle for

the wire rope magnetic testing, put forward

adopting. Equivalent rusting concept to achieve

rustiness quantitative evaluation. By the

Equivalent Rusting Concept we mean proceeding

from the wire rope intensity, analyze the

different rustiness degrees have influence upon

the wire rope intensity. To combine the magnetic

testing result and give out a quantitative

target, ascertain the application state for the

wire rope. Make a analysis in the concrete,

inspect out the pitting etc local flaw of wire

rope with leakage magnetic field testing method.

Taking their signal intensity and feature are

compare with the broken wire signal, ascertain

the wire rope concern between the pitting degree

and broken wire number.

Adopt

magnetic bridge circuit principle inspect out

the corrosion etc, large areas flaw for the wire

rope, ascertain after the rustiness, the

efficacious metallic cross-sectional areas to

combine the intensity theory and give out the

practice load bearing cross-sectional areas.

(4)

The evaluation of testing results for wire rope

state

The

aim of wire rope testing is that not only

obtains the geometric parameter of overall

accuracy, but also provides the requisite

parameter of wire rope intensity, lifetime

evaluation, proceeding to provide the basis for

practical wire rope change. There fore, it is

necessary/reasonable that the testing result

would enable to be connected with the requisite

parameter for the wire rope evaluation. At

present, evaluating wire rope state start with

wire rope intensity respect in general. However,

the difference of accepting force and scrap

condition for wire rope are very great for the

geometric shape complexity and the application

condition change of the wire rope, thus, the

evaluation of the wire rope intensity lack the

parameter with instrument testing. The internal

and external department concerned evaluates the

wire rope major basis with wire rope testing

result basically. And then combine with damaged

experimental result of the wire rope. Here, we

ascertain the wire rope state with the practical

metallic loss as the major target. Here, by

practical metallic loss is meant the loss of

wire rope metallic function including the flaw

of broken wire, abrasion, rustiness, fatigue

etc. This loss is corresponding with the certain

testing signal of the wire rope.

①

Evaluation basis of non-destructive testing for

wire ropes

It is

known to all that the important feature for wire

rope cant be disrupted suddenly. Because of the

complexity for wire rope structure, it bears the

combining action such as stretching, bending,

squeezing, torsion, etc. in the course of

manufacture. There fore, the wire rope bears

force state very complex. Every piece of wire

rope is composed with some dozen of wires. It is

a statically indeterminate system many scholars

desire to solve the each wire internal force

with high order partial differential equation,

precede to evaluate the operation life for wire

rope. But, it is very different to use in

concrete practice. They have many influence upon

the operation life factor for wire rope such as

stress (wire rope stress), in proportion as the

diameter between wheel and wire structural form

and material quality for the wire rope, twining

technique, lubricating condition, environment

temperature, glide wheel material quality, rope

score shape of glide wheel. Etc. It is difficult

for many factor to calculator the operation life

with a formulation accurately. There fore, every

country is grounded on experiments and

industrial application experience to ensure

selecting wire rope with enough statically